What are 3D filaments used for?

3D printing filament is the thermoplastic feedstock for fused deposition modelling 3D printers. There are many types of filament available with different properties, requiring different temperatures to print. Filament is commonly available in the two standard diameters of 1.75 mm and 2.85 mm.

Different types of filaments

PLA

One of the two most often used desktop 3D printing materials is PLA short for ‘Polylactic Acid’. PLA is the “standard” suggested material for many desktop 3D printers, and for legitimate reason: it is helpful in a wide variety of printing applications, is unscented and low-warp, and so does not require a heated bed. PLA filament is also one of the most environmentally friendly 3D printer materials on the market; it is manufactured from yearly renewable resources (cornstarch) and takes less energy to process than traditional (petroleum-based) plastics.

Summary

- The best 3D printer material for beginners because of its simplicity of printing and low warp.

- PLA filament is a sturdy yet brittle 3D printing material.

- Cosmetic prints, prototypes, desk toys, and low-stress applications are ideal.

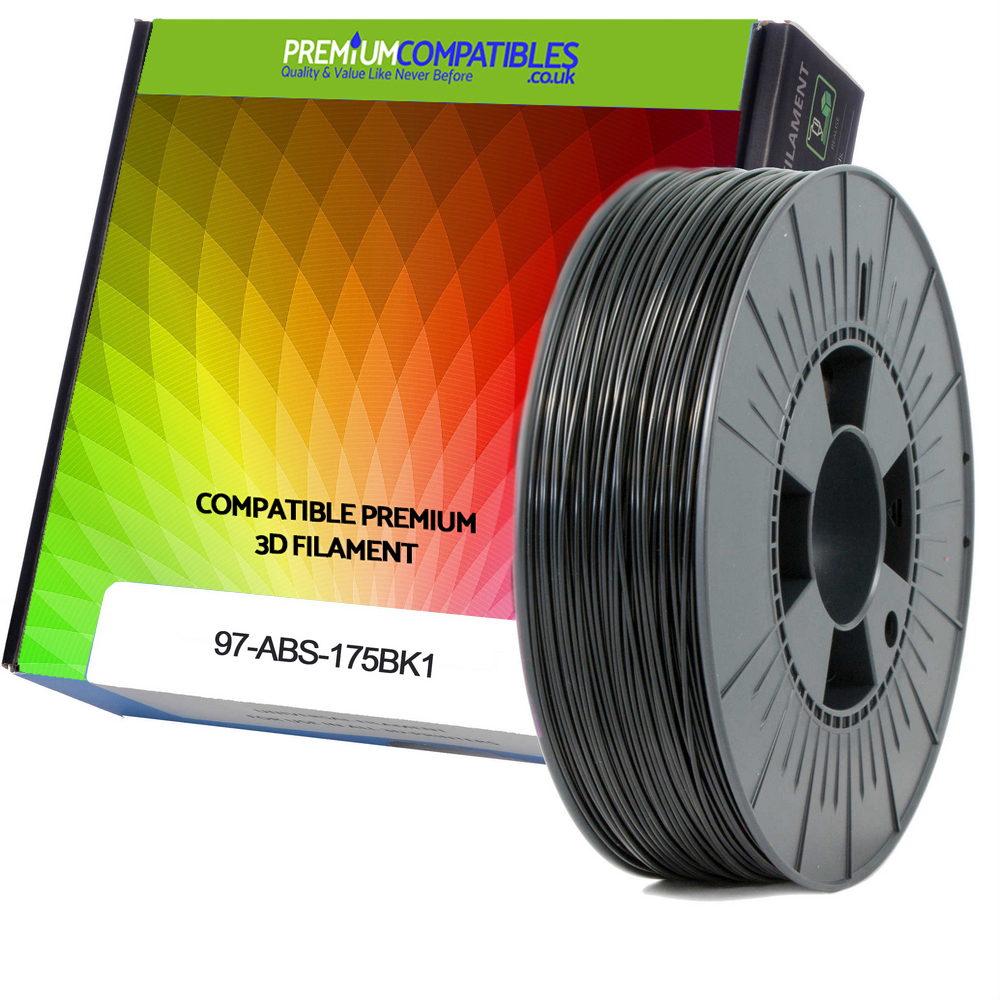

ABS

Another popular 3D printer material is ABS (Acrylonitrile Butadiene Styrene). ABS filament is available in two diameters: 1.75mm and 3mm. Best suited for producing long-lasting parts that would endure higher temperatures. ABS plastic is less stiff and more pliable than PLA filament. Polishing it with acetone can help provide a glossy appearance. A warm printing surface is suggested for 3D printing with ABS filament, as ABS material contracts when cooled, resulting in misshapen pieces.

Summary

- ABS filament is a tough, ductile material that is resistant to wear and heat.

- Interlocking pieces like gears, parts exposed to UV and heat like a vehicle cup holder, and prototyping are all common 3D printers using ABS.

- Wide ranges of solutions are available for great post-processing.

PET

Most PET filaments are copolymers (PET with an additional molecule), therefore finding real PET (Polyethylene terephthalate) filament will be difficult. PETG filament, the most prevalent, is an industrial grade filament with numerous amazing properties. In a metaphorical way, it offers the convenience of PLA filament with the strength and durability of ABS filament. For starters, it has a lot higher strength than PLA and is FDA approved for food containers and food consumption instruments. Unlike ABS filament, it does not warp and has no scents or gases when printed. PET filament is not biodegradable, however it is completely reusable. It’s well known for its lucidity and bridging abilities. PET 3D printing filament comes in 1.75mm and 3mm widths.

Summary

- PET filament is a tough and versatile 3D printing material with a polished finish that is impact and heat resistant.

- Mechanical parts and snap fit enclosures benefit the most from this material.

- It adheres exceptionally nicely to blue painters tape.